Growing numbers of craft breweries turning to Australian designed ‘bev-tech’ for energy and cost-saving benefits

Content published as an Announcement is produced by the business(es) named in the announcement and remains unedited by Brews News.

With the triple whammy of interest rates and rising energy and operations costs hitting all Australian businesses, growing numbers of craft breweries are turning to a locally designed technology solution to reduce their energy consumption while improving their work-life balance.

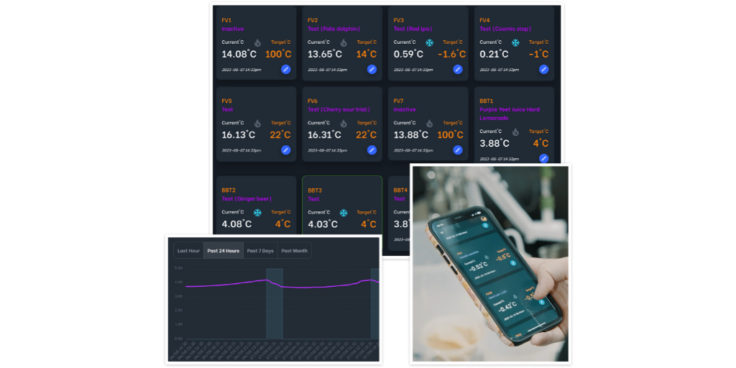

Frigid is a cloud-based fermentation platform with a vision to provide brewers with cost effective monitoring, control and automation while using less energy. Fundamentally, Frigid replaces a traditional manual control system and allows brewers to monitor and control their ferments from anywhere, anytime. The system leverages the existing infrastructure in the brewery without the need for proprietary probes or sensors making it not only cost effective but also extremely flexible.

Reece Wheadon from Perth based Nowhereman Brewing Co said “Frigid allows us to keep an eye on our ferments and gives us peace of mind that everything is on track while we’re away from the brewery.”

With a firm focus on sustainability, Frigid’s replaces the traditional “first in last out” approach to cooling tanks and instead uses pulse cooling which has been tried and tested in the wine industry for years. Not only is this a more efficient way to cool ferments, it also means the chiller isn’t working as hard to refrigerate the glycol. In a case study run at Little Bang Brewing in Adelaide over the course of a month, the results showed a 25% decrease in kWh usage from the chiller. Given refrigeration is generally a large contributor to energy costs at a brewery, this saving can be substantial and in some cases it is more than covering the subscription to the platform.

Furthermore, if your brewery has solar then you can leverage Frigid’s thermal storage module. This integrates with your solar PV and when there is surplus energy it will overchill your glycol tank and effectively turn it into a thermal battery. Then, once the sun has gone, it will use that thermal mass before needing to run the chiller.

Adelaide’s Big Shed Brewing head brewer Ben Johnson said: “Frigid’s pulse cooling system enables us to use our equipment smarter, be more efficient and reduce our carbon footprint.”

Frigid was originally conceived and designed to provide brewers with real time information and the ability to control their refrigeration or chilling process remotely – something that traditionally only large multinational brewing companies have had access to. Using loT (internet of things) devices and cloud computing, the solution also significantly increases productivity and reduces energy consumption by optimising when and how it draws energy across the brewing process.

Independent Brewers Association national CEO Kylie Lethbridge said “given the current economic climate many of our members are trying to find ways in which they can be more efficient and to save costs”.

“Sustainability is important to our industry and so it is not surprising that Frigid is becoming a well-recognised name in the independent brewing sector,” Ms Lethbridge said.

“It is for this reason we are proud to support their efforts as they support our organisation and lead the way in cost effective and innovative technology.”

Frigid will be heading to BrewCon so please stop by stall 92 to chat to the team and find out more about how the platform can make a difference for your brewery or visit https://frigid.cloud to get in touch.