Brewers beware, diastaticus spells disaster

Exploding bottles. Multi-million-dollar large-scale recalls. Microscopic culprits.

Whilst the public love reading about high profile recalls, brewers shiver. A single S. diastaticus cell can rupture packaging and bring breweries to their knees.

Saccharomyces diastaticus is a gene mutation of the common brewer’s yeast Saccharomyces cerevisiae. This gene can cause unintended secondary fermentation, building pressure in sealed cans or bottles, causing an explosion risk, and altering alcohol content. If detected early, aggressive mediation can prevent expensive recalls and lasting brand reputation damage.

This article is brought to you by BREWSTAT powered by VERIFLOW. BREWSTAT PCR testing gives you confidence that S. diastaticus is not present in your brew with proven fast, accurate, and sensitive results. Perfect for breweries of any size.

What’s happening at a chemical level?

The S. diastaticus mutation is identified by the STA1 gene, which causes the organism to produce the glucoamylase enzyme. Glucoamylase acts by converting unfermentable dextrins and starches into fermentable sugars such as glucose. S. diastaticus and other remaining beer yeast are then able to referment these sugars, resulting over attenuation (dry beer) and causing an explosion risk.

Diastaticus is challenging to control, as it multiplies rapidly at room temperature and can hide in beer lines, causing a biofilm, which can reinfect future batches. For consumers, this means excess carbon dioxide, gushing, phenolic off flavours (POF), and a cloudy appearance.

It is recommended to routinely monitor for S. diastaticus, to minimise risk to consumers and protect the quality of finished beer.

Where should brewers check for S. diastaticus?

- Primary contamination: yeast/fermentation cellar

- Secondary contamination: filling process

- Source:

- Residues in bottles

- Biofilms

- Air circulation around filling machine or capper

- Insufficient heat treatment

- Dry hopping

- Wort ingredients

- Airborne particles from keg washers

- Control Points to check:

- Yeast slurries (propagating/re-pitching)

- Incoming yeast

- Fermenters or bright tanks

- Packaged cans/ bottles

- Keg washers and recycled kegs

- Source:

Without appropriate tools, S. diastaticus can be challenging to detect as it is almost identical to S. cerevisiae. S. diastaticus is active at low levels, meaning that by the time a noticeable difference is detected, it is too late.

How to detect and manage S. diastaticus?

Brewers have 2 options available: Agar plates & polymerase chain reaction (PCR).

Agar plates, while more economical, can take weeks to produce a result and can not easily distinguish between S.diastaticus and S.cerevisiae due to them being -morphologically similar.

Many brewers prefer PCR tests due to their speed and accuracy. BREWSTAT detects the STA1 gene target specifically and enables early detection through actionable results in as little as 4 hours.

Benefits of BREWSTAT:

- Prevent processing and bottling contamination risk

- Early detection of potential issues

- Allows traceability to the point of contamination

- Reduces the risk of further contamination

- Protects against recall of infected beer

How to use BREWSTAT PCR Testing:

COLLECT

Collect a homogenous sample and centrifuge. Resuspend sample using Buffer .

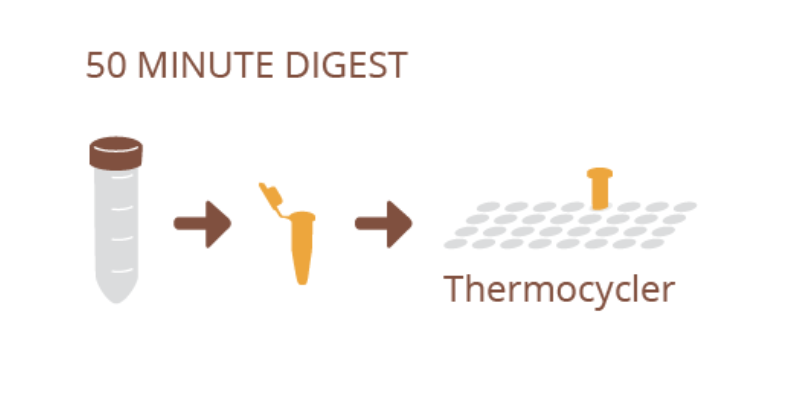

DIGEST

Transfer resuspended sample into provided DIGEST reagent tube. Place tube into Thermocycler and run program.

APPLIFY (PCR)

Transfer sample from DIGEST reagent tube into provided PCR reagent tube. Place tube into Thermocycler and run program.

ANALYZE

Remove PCR Tube from Thermocycler and add Buffer. Dispense PCR Tube contents onto test cassette window. Wait 3 minutes and retract test cassette switch to reveal test results. One line indicates negative result, two lines indicates semi-quantitative positive results.

If you would like to learn more about BREWSTAT by VERIFLOW, contact us at AMSL Scientific.

E: scientific.enquiries@amsl.com.au

P: 02 9882 3666