Three steps to designing your perfect brewhouse

Bespoke Brewing Solutions offer advice on how to design your perfect brewhouse to maximise productivity and efficiency.

Your brewhouse is the heart and soul of your brewery.

For many brands, it is the centrepiece of the space, tying everything together. If the space is nice to look at, it can also serve as the primary attraction to get people in the door.

Putting aesthetics aside – a well-designed brewery can also lead to huge cash savings. Time is money – so we design our brewhouses to reduce time spent on tasks. Poor brewery design leads to poor processes.

This leads to inefficiencies and over-extended resources.

We acknowledge many elements of brewery design come down to preference and opinion. However, there are some staples to getting it right that we follow, to give our clients the best results.

When we are helping a client lock in their brewhouse design, we focus on three main factors – heating method, configuration and controls. (To help everyone keep up, we have created this handy Glossary of Terms.)

MT – mash tun

LT – lauter tun

KT – kettle

WT – whirlpool

MLT – mash and lauter combination tun

KWT – kettle and whirlpool combination tun

HLT – hot liquor tank

CLT – cold liquor tank

Brewery Heating Method

Your heating method could possibly dictate your entire configuration. This makes it a critical decision for your brewery.

The heating methods we offer are steam, direct-fire and electric – and in our humble opinion, steam is generally the best option.

Before deciding on your heat source it is best to look at your site and the utilities coming in.

We ask you questions like:

- Do you have a natural gas line?

- Can you put gas bottles onsite? (These are important for gas steam boilers or direct-fire.)

- What are your electricity costs? (This is important for electric heating elements and electric steam boilers.)

Method One: Steam Heating

We like this one primarily because it gives you efficiency (make sure to return the condensate) and flexibility.

A steam heating method allows you to perform step mashing in a mash and lauter combination vessel. Not to mention steam can be used in other equipment in the brewery, for example cleaning and packaging equipment.

We can also utilize external HEX for hot liquor tanks. This is so you can heat your ambient water coming in – but you’ll also see faster temperature gains altogether by recirculating liquor in the HLT.

The same method of employing a HEX for steam heating can be used on the cold side for cooling liquor in the CLT, with exactly the same process as described above, but using glycol as opposed to steam.

When it comes to installation cost, it is typically the most expensive option. Steam boilers are expensive and installation of steam lines and componentry is also pricey. In terms of maintenance and upkeep, the steam boilers require professional engineers to maintain the longevity of these units, so choosing the best boiler supplier is crucial.

Pros: flexibility, efficiency, multi use around the brewery, fastest heating.

Cons: expensive installation, regulations and maintenance.

Method Two: Direct-Fire Heating

Picture this – a big flamethrower, aimed at the bottom of a vessel, via a firebox.

This is essentially a direct-fire system! The burners used are intense, but you will get a good rigorous rolling boil with a direct fire flame.

At Bespoke Brewing Solutions, we prefer this option over electric. This is because you can start heating shortly after covering the bottom of the kettle like steam.

Pros: cheap installation, low maintenance, faster heating

Cons: least efficient, single infusion mashing, more expensive due to the firebox

Method Three: Electric Heating Method

This can also be fairly expensive, depending on your electricity rate.

This is why we generally don’t recommend this heating method for anything over 7BBL or 10BBL – unless you have super cheap electricity.

You can get good boils from heating elements. However – they can also prove problematic for cleaning and whirlpooling, as they can disrupt the effects.

Pros: cheapest installation, low maintenance (but can be expensive depending on electric bill)

Cons: not the best when using a kettle and whirlpool combination vessel, scorching of wort, no heat source for mash tun

Alternatives

As a fun fact, our team is actually working on a project right now which will use a thermal fluid system! We are excited to see how that works out, and it will be an interesting challenge for us to undertake.

We have also worked with Lanemark Combustion Engineering on a gas burner solution utilizing a coil inside of the kettle (or copper as they say in the UK).

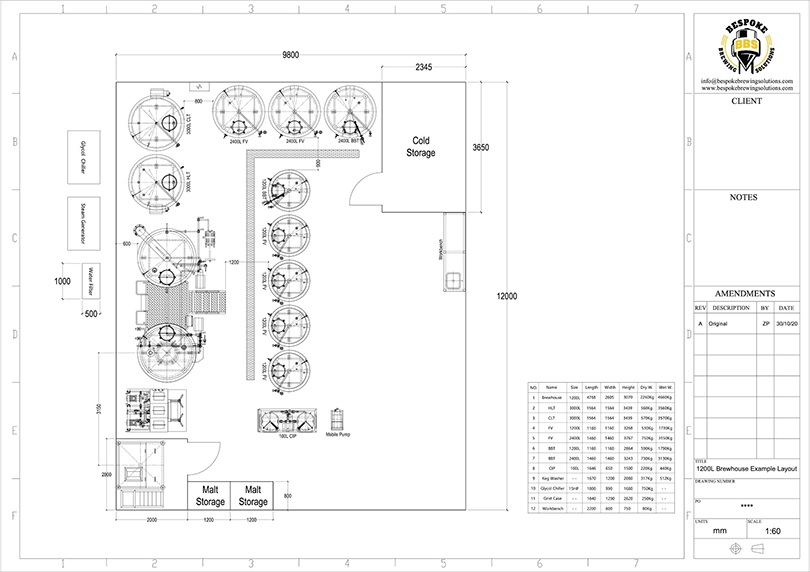

Sample layout of a 1200 litre brewery

Configuration

Over the years we have designed many different combinations of systems.

We’d have to say the most common would be our 2-vessel with a mash and lauter combination vessel – and kettle and whirlpool combination vessel. With a 2-vessel system you can do double brews – but they can prove to be long days!

We advise you to look into a 3-vessel system once you have the need to do 2+ brews a day.

We have mainly done the configuration of mash tun, lauter tun, and kettle and whirlpool combination vessel – but have done mash and lauter combination vessel, kettle and whirlpool.

Each has their own advantages and disadvantages and it really depends on the brewer and beer styles.

Beyond a 3-vessel solution you get into a 4-vessel or even 5-vessel brewhouse. This splits each process out into its own vessel and you are then able to really push out some volume.

We are currently working on a project which will be implementing a 2nd stream as they grow. This will utilise 1 mash tun and then split to 2 different lines containing a lauter tun and kettle and whirlpool combination vessel.

Controls

The primary control methods are manual and semi-automatic (varying degrees) and fully automatic (not seen a lot in craft).

When we design a manual system, we generally try to make the bulk of valves and componentry in 1 or 2 locations. This is to avoid the brewer having to constantly be forced to move around the brewhouse.

We also implement a double control panel design, with functionality crossing between both. This way the brewer is not constantly running up and down the stairs to adjust pump speeds, turn on rakes, etc.

Hot Tip: Your liquor tanks play a very important role in the brewhouse. You should consider the sizing and positioning when deciding on your brewhouse design. They are very much correlated and really depend on each other.

The Bespoke Difference

At Bespoke Brewing Solutions, we don’t believe in a ‘standard’ approach.

Each of our clients is unique. Therefore, they are given their very own, custom-designed brewhouse. Each design is different from the next – we have never built the exact same brewhouse twice!

We work to take everything into consideration – the size and shape of the space, the physical location, utilities – and most important, the needs and wants of the brewer.

But the two most important details are – what you’re trying to achieve and the type of beer you’re planning on brewing.

So contact our team if you want to work with exports on your brewery design.

And as a side note – if you have read this article and you’ve got some thoughts about some of the ideas we have put out there, get in touch,

We put this piece together to help people and share the knowledge – but we understand there are many different ideas out there, around brewhouse design,

Want to learn together! So we are keen to hear your feedback and comments.