Using hop certificates of analysis to optimise brewing June 2020

Hop Products Australia analyses every batch of hops and brewers can use the resulting Certificate of Analysis to anticipate how every batch of hops will impact their final brew. Here’s how…

Quality management in ingredients is vital to the end quality in beer and so Hop Products Australia employes a range of quality management procedures to ensure their farms and facilities are ISO 9001:2015 compliant and HACCP certified.

Beyond that they analyse more than 3,000 hop samples every harvest to generate more than 25,000 measurements to ensure their hops deliver consistent flavour outcomes year-on-year.

For brewers, understanding this pre- and post-harvest hop analysis is key to producing beer of consistent quality. Hops are a natural ingredient, which means they are subject to seasonal variation. Hop analyses give hop growers and brewers alike the opportunity to optimise their processes to achieve consistency and efficiency.

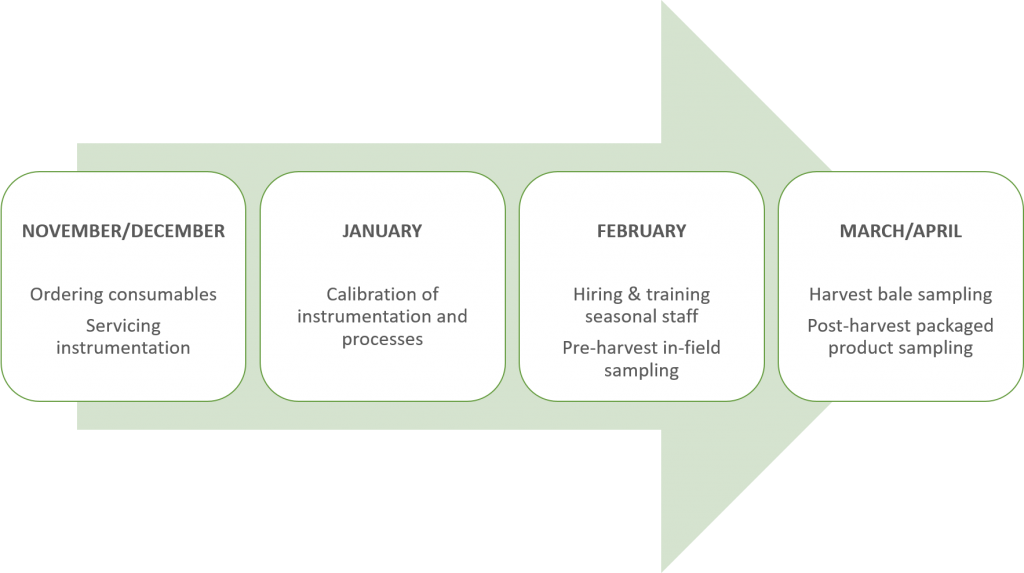

The sampling process

The hop sampling and measurement process spans a period of six months. During this time, HPA goes through three phases on quality testing – pre-harvest in-field samples, harvest bale samples and post-harvest packaged product samples:

Pre-harvest sampling

Pre-harvest sampling tracks the development of hop cones and the accumulation of alpha acids and essential oils across our farms. Every paddock across across HPA’s farms is systematically sampled at least three times with the final sample taking place within 36 hours of the paddock being harvested.

The information received from these samples confirms whether HPA’s planning around harvest logistics is correct, and informs the picking sequence for varieties that cover significant acreage. This picking sequence ensures the best possible representation of each variety is captured year-on-year.

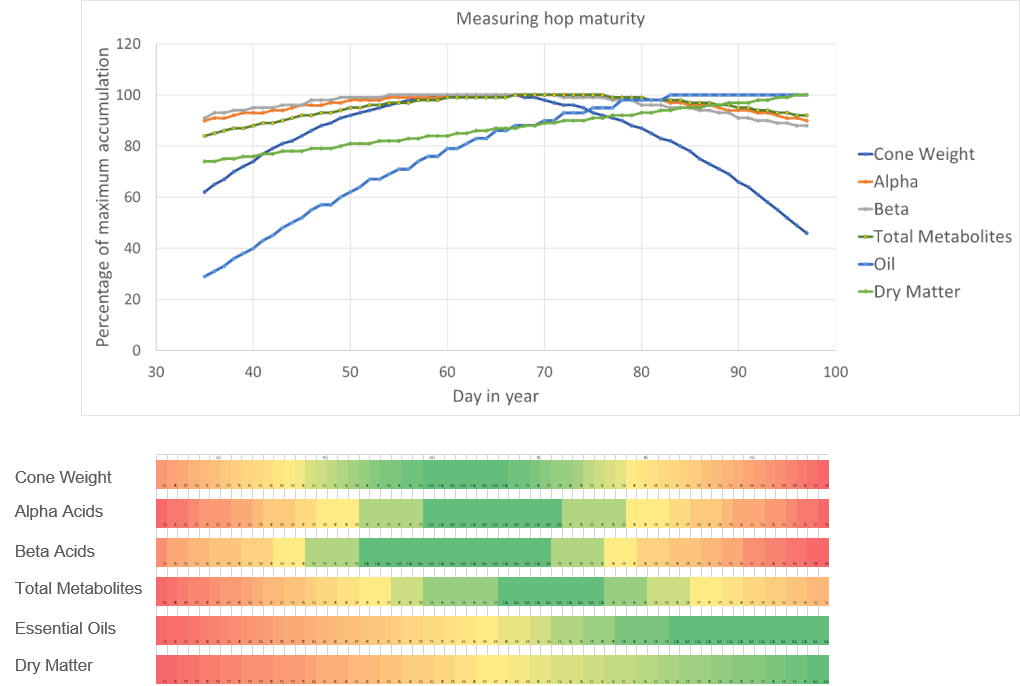

Each samples’ alpha acids and oil content are assessed through a near-infrared (NIR) analytical system. Gland fill, dry matter and cone weight are also measured at this stage. All of these measurements follow a fairly consistent pattern of development in the lead up to harvest. Harvest occurs only when the paddock reaches ideal values.

The graph and heatmap below show the day in year that these values are typically reached. However, events such as hot and windy days, heavy rain, flooding or frost can accelerate development.

During harvest several composite samples are taken from each lot of hops once they have been baled. Alpha acids and moisture content are the main focus at this point with all measurements produced through NIR. This is crucial to the blending process that enables us to achieve consistent quality outcomes for each variety year-on-year.

Post-harvest sampling

Post-harvest HPA conducts further testing on each lot of final packaged product, including pellets and flowers. This information is what brewers see on certificates of analysis (CoAs).

Brewers can use CoAs to anticipate process changes required to achieve consistent brewing results, and to verify compliance with hop specifications.

HPA supplies its hops in sealed, oxygen barrier laminated foils that have been back-flushed with carbon dioxide and packed in cardboard cartons. Each carton is labelled with variety, producer, crop year, production date, lot identification number, product type, net weight and bittering potential (alpha acid contents and analysis method).

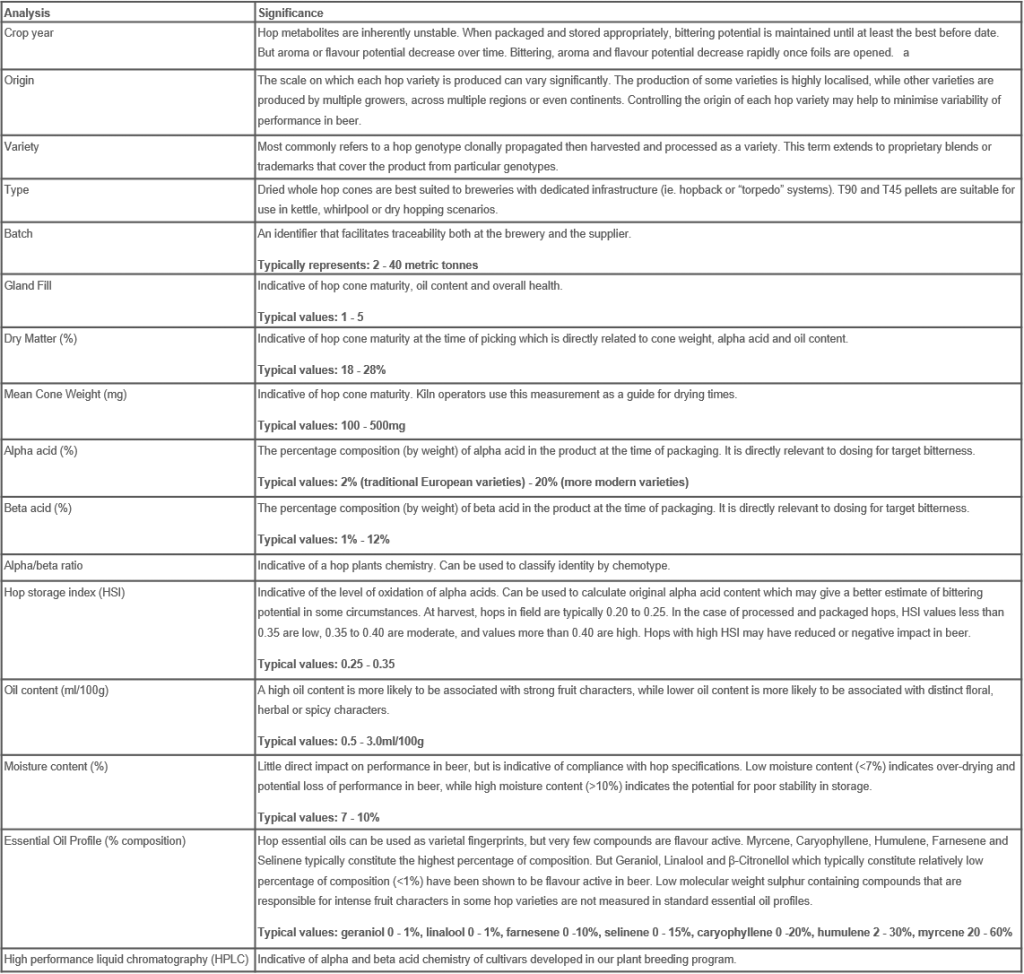

There is no standardisation of hop CoA information in the brewing industry. In its most basic form a CoA will cover the same information as the carton labels, but we also choose to include essential oil content, moisture content and agricultural chemical residue reporting.

Each hop analysis has a different significance in brewing:

Since hops that are used in brewing are a food ingredient, producers are required to ensure all typical food safety requirements are met, and can also provide allergen and residue statements if required.

It is also important to remember that hop CoAs and label information describe the hops at the time of packaging. Chemical changes that affect performance in beer may occur if the hops are transported, stored and/or handled improperly at any stage of the supply chain.

We work closely and collaboratively with our contractors to ensure this risk is managed effectively, so that our customers can continue making great tasting beer.

Now you understand the role of the Certificate of Analysis, learn how to keep your hops fresh even when opened.

To learn more about Certificates of Analysis and how you can interpret them for your own brewing, speak with your Hop Products Australia representative.